Special challenges in the bulk goods industry

Whether the finest of powders or the coarsest of pellets, bulk goods differ in density, surface and size – and thus also in flow behaviour. Some are corrosive, others create extreme quantities of dust, or are explosive when they come into contact with air.

To safeguard plants, as well as to protect machinery and operators, components and switches must be optimally suited to, and able to withstand such extreme ambient conditions, while at the same time meeting high IP and Ex protection standards.

With our product range certified to European and international standards and regulations, we are able to meet the complex challenges of the bulk goods industry and facilitate reliable safeguarding of machines and plants.

DSIV

We are a specialist for Ex-protected safety switches and sensors, have years of experience and are a member of the German Bulk Goods Association (Reg. Ass.)

Safety first: reliable switchgear

Depending on the variant chosen, our multi-faceted product range is certified to European and international standards and directives (ATEX, IECEx, cCSAus, INMETRO, CCC, UKEx) for Ex zones 1, 2, 21 and 22, and is excellently suited to the extreme ambient conditions found in the bulk goods industry.

Our corrosion-resistant and Ex-protected products, such as Ex solenoid interlocks, Ex safety switches and Ex safety sensors, ensure that e.g. easily flammable powders can be processed, transported and stored reliably, and that both process safety and operator safety are guaranteed in dusty and explosive areas.

In order to ensure both the functionality and the quality of our products years down the line, the steute switching devices are artificially aged by approx. 10 years by placing them in a climate chamber for a period of 4 weeks. In addition, all products for use in Ex-zones 1 and 2 (gas-Ex) or 21 and 22 (dust-Ex) are submitted to an impact test to ensure their mechanical strength. A testing mass made out of reinforced steel falls onto the product with 7 J from a pre-defined height.

Internal laboratories test product reliability

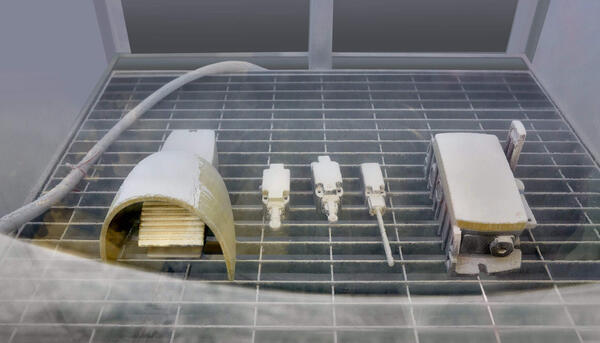

In order to optimise our switches and sensors for the special requirements of the bulk goods industry, steute products are tested in internal laboratories. A dust system simulating the relevant environmental conditions is used for testing to standards DIN EN 60529 (IP5X / IP6X), ISO 20653 (IP5KX / IP6KX) and SAE J 575. These IP protection classes define the protection of active, i.e. live parts from touch, as well as from water penetration. Devices for the bulk goods industry require protection class IP6X.

The enclosure is placed inside the test chamber, and the pressure inside the enclosure maintained below the surrounding atmospheric pressure by vacuum pump. The goal is to suck an air volume equalling the 80-fold volume of the enclosure into the chamber. In the meantime, a dust device rotates inside the test chamber, dispersing talcum powder. The test medium used is 2.5 kg talcum 22/HK.

The test unit is connected via cable entry to the internal vacuum pump of the dust chamber. The vacuum pump is set to achieve a negative pressure of approx. 20 mbar.