Special requirements

Extreme weather conditions, fine dust or heavily vibrating machines and plants: the challenges encountered in conveyor technology, for example in mining, are enormous. The conveyor systems sometimes stretch for kilometres and must reliably transport materials and raw materials which may be wet or dusty. If a conveyor is loaded unevenly or the belt is no longer aligned between its rollers, then the belt must be corrected or the conveyor stopped immediately.

In many other branches of industry, conveyor technology is also an essential part of production and loading, thus contributing significantly to the efficiency of diverse applications. Due to the strongly growing international competition, especially in the field of automation technology, most areas are under enormous pressure to optimise their production processes. This makes the reliability of conveyors all the more important, as well as their ability to be stopped directly and safely should a problem or hazard occur.

Switching devices for safeguarding conveyor technology

Depending on the application field and branch of industry in question, switching devices must be deployable in different conveyor systems and in very rough environments, while at the same time meeting the requirements of safety, corrosion resistance and robustness. The emergency pull-wire switches from steute facilitate, for example, reliable emergency stops and belt-rip detection in larger plants. Our belt alignment switches monitor the correct alignment of conveyor belts and thus safeguard the transportation of heavy bulk goods.

In addition to safety products, steute offers a wide range of switches and sensors which promote the automation and optimisation of production processes. Wireless sensors and position switches, for example, can be flexibly used for the automated counting and monitoring of piece goods in production processes.

Our robust switches and sensors are optionally available with high IP protection and as explosion-proof variants.

Conveyor belt set-up

- Emergency stop function

- Emergency pull-wire switches guarantee a reliable emergency stop function including wire-break monitoring on conveyor systems

- One-side actuation up to 100 m and two-side actuation up to 200 m

- Belt position monitoring

- Staggered contacts allow for a warning signal to initiate a belt correction

- Switch-off after further actuation of the belt alignment lever

- “Advance warning contacts” reduce standstill time of the conveyor-belt system

- Belt-rip detection

- Automatic switch-off of the equipment with overloaded or ripped conveyor-belt

- Extensive range of accessories

- Compensation spring ZS 90/91/92 S

- Pull-wire Ø 5 mm

- Eye bolt open M 10 x 150 with 2 nuts

- Cable Tensioner System TS 65

- Pulley Multiflex 4R

Emergency-stop function with robust emergency pull-wire switches

The emergency pull-wire switches in our ZS 92 S series were developed especially for extreme environments and applications. They are optionally available with a very robust die-cast aluminium enclosure with multiple coatings (passivation, primer, powder coating) or alternatively a high-quality thermoset enclosure. Our range includes 2G/D variants for Ex zones 1 and 21, as well as 3D variants for Ex zone 22.

The ZS 92 S emergency pull-wire switch assumes the emergency-stop function along conveyors, can be actuated at any point along the wire and contributes significantly to personal and machine safety.

Rear and base mounting possible

The ZS 92 S series can be mounted both from the rear and from below. The mounting dimensions are compatible with other emergency pull-wire switches on the market, simplifying retrofitting or replacement within existing conveyor systems.

Optionally available as a Dupline safe variant

The ZS 92 S emergency pull-wire switch is optionally available with an integrated 8-pole Phoenix multi-way connector and bracket for safety bus module. The safety bus module is available as an accessory in different versions and facilitates connection to the “Dupline safe” protocol.

Extremely flexible thanks to various settings

The ZS 92 S emergency pull-wire switches are available with different settings for the actuation lever and the release lever. They can therefore be installed more or less anywhere.

LED indicator lamp

The ZS 92 S emergency pull-wire switch is optionally available with an LED indicator lamp. This lamp lights up red when the emergency pull-wire switch is actuated, making it possible to see immediately where along the conveyor belt the stop was initiated and intervention is required.

Comprehensive and innovative accessories for emergency pull-wire switches

Emergency pull-wire switches are crucial to safety in plants with industrial conveyors. They facilitate the triggering of an emergency stop anywhere along the belt. But in order to exploit the full potential of these switches and adapt them to individual requirements, it is vital to have the correct accessories. In the following, we will present a few tried and tested accessories which can increase the functionality and flexibility of emergency pull-wire switches.

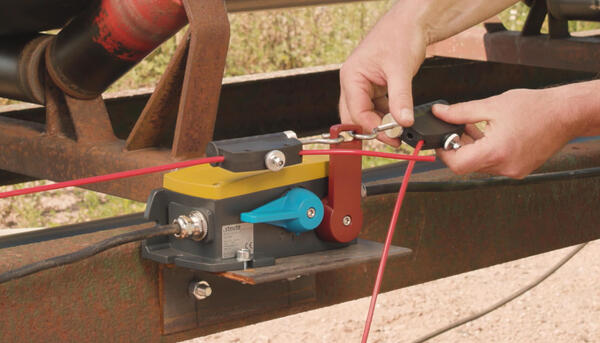

Installation contest: TS 65 wire tensioner vs. conventional pull wire installation

TS 65 wire tensioner - quick, easy, efficient!

Fewer steps, more efficiency! Our expert Matthias Schara challenged himself at the Rhein-Umschlag gravel works to perform an installation contest: the widespread conventional method of pull-wire installation using turnbuckles, cable clamps and thimbles against state-of-the-art installation using the innovative TS 65 wire tensioner from steute. The result: the complete pull-wire installation took over 9 minutes versus just 42 seconds! The TS 65 wire tensioner not only saves a considerable amount of time, but also significantly reduces the number of necessary steps and tools.

Perfect team

Particularly in plants where many switching devices are installed, the factors time and ease are very much a focal point. Holding on to conventional methods can hinder efficiency. For simplifying installation and saving not only time and money, but also manpower, the combination of a ZS 92 S pull-wire switch and a TS 65 wire tensioner is unbeatable. See for yourself in our new video.

Additional accessories for emergency pull-wire switches

Compensation spring ZS 90/91/92 S

- With travel limitation

- Adaption of length expansions caused by changes in temperature

- Version consisting of: stainless steel chain, 2 carabiner galvanized and tension spring

Eye bolt open

- 150 mm length, 70 mm thread length

- M10 thread

- Galvanized steel

- 2 hexagon nuts are provided

Pulley Multiflex 4R

- To guide the pull-wire up to max. 60°

- Low friction

- Flexible installation

- Rotating head (360°) automatically adjusts the wire even when the wire is pulled

- Movable rollers inside the opening of the pulley

Pull-wire Ø 5 mm

- Steel core or stainless steel core Ø 3 mm with red PVC sheath

- Total diameter 5 mm

- Ordering unit: per metre

Here you will find a comprehensive overview of our versatile accessories for emergency pull-wire switches.

Position monitoring of conveyor belts using freely adjustable belt alignment switches

The belt alignment switches in our ZS 92 SR series are true specialists when it comes to extreme environments. All products in this series feature outstanding mechanical robustness and come either in a die-cast aluminium enclosure or a thermoset plastic enclosure (-KST). Also available are the Ex ZS 92 SR-2D (for dust Ex zone 21) and the Ex ZS 92 SR-3D (for dust Ex zone 22), both in a die-cast aluminium enclosure.

Our belt alignment switches monitor the straight course of conveyor belts. A large stainless steel roller lever swings to one side if the belt is no longer aligned between the rollers, for example because it is unevenly loaded. Depending on the control settings, this can either enable a correction of the belt or stop the entire conveyor. Its robust construction and special design for extreme environments make the ZS 92 SR series a reliable solution for complex applications.

Staggered contacts facilitate advance warning to enable timely belt correction

A truly outstanding feature is staggered contacts with individually adjustable switching points. The switching points for advance warning and for shutting off the conveyor can each be set within a range of 5°-35°. All that is necessary is a simple unlatching, shifting and relatching of the switch inserts. The switch can then first send an advance warning, and only if the lever swings out further will the conveyor shut down. These "advance warning contacts“ reduce standstills: the operator has a chance to intervene before the belt stops.

Different variants for roller lever adjustment

Some variants have a self-locking shaft (positive engagement), enabling the shaft to be changed quickly, while others have a continuously adjustable shaft, enabling the the default position of the roller lever to be adjusted to the individual application case.

LED indicator lamp

The ZS 92 SR belt alignment switch is optionally available with an LED indicator lamp which displays the switching state. This makes it possible to see along the conveyor from a distance where exactly the belt is no longer aligned.

Innovative wireless solution for belt alignment monitoring

Combining our tried-and-tested ZS 92 SR belt alignment switch with a separate RF I/O radio module has opened up new possibilities for efficient and interference-free conveyor control. Using sWave technology, a transmitter unit sends the signals coming from the switch to a wireless relay component which functions as a receiver. The transmission functions reliably and without cables over distances of up to 400 metres in the field. Additional repeaters can be installed for greater distances.

This robust wireless switching system has considerable benefits, especially in adverse environments, and unites the core steute competences switchgear and wireless technology.

Innovative belt-rip detection system

Do not let a simple rip in your conveyor belt lead to catastrophic failure and costly downtime. The ZS 71 belt rip detection switch and wire system can safeguard your operations by providing early detection and swift action. With its belt-rip features, robust construction, and user-friendly design, the ZS 71 belt-rip detection switch offers peace of mind and uninterrupted productivity. The ZS 71, combined with the comprehensive wire kit, offers a complete solution for belt-rip detection. When a rip occurs in the belt, any material or ripped section of conveyor belt caught by the wire activates the switch, halting the conveyor operation.

With its quick detection and immediate action upon belt rip occurrence, the switch significantly minimises conveyor system downtime, saving you valuable time and resources. The ZS 71 belt-rip detection switch is compact and designed to fit perpendicular to the conveyor belt, even in restrictive spaces.

Belt-rip detection system set-up

- Belt-rip detection switch ZS 71

- 1 x carabiner (stainless steel)

- 1 x key ring (stainless steel)

- 1 x safety decoupler

- 2 x plastic clamp

- 5 m steel wire, Ø 3-5mm PVC red

- 1 x wire tensioner TS 65

- 2 x BM 8 x 70 eye bolt (stainless steel) with 2 nuts

- 2 x wire guide (stainless steel) with 2 x M10 nuts and washers

Conveyor belts can be safeguarded with either one or two belt-rip detection switches.

Wire system

The integrated safety decoupler safely decouples the belt-rip detection switch from the wire system if there is a mechanical overload (>250 N). It is easy to reattach.

References

Our solutions are used all over the world in a wide variety of projects and fields throughout many different branches of industry. Here you can find a selection of renowned companies which successfully deploy steute products:

Herrenknecht / H+E Logistik GmbH, Germany

(tunnel boring machines and tunnelling)STM Industriale S.P.A., Italy

(conveyor systems)Rhein-Umschlag GmbH, Germany

(gravel and sand works)Mineraria Ligure S.r.l., Italy

(manufacturing of powders, pebble stones and marble granulates)VHV Anlagenbau, Germany

(conveyor technology)alco energy, Netherlands

(biorefinery)ABB, Germany

(automation)AMAGGI Exportacao e Importacao Ltda, Brazil

(processing of grain and fertilisers)CENIBRA Celulose Nipo-Brasileira S.A., Brazil

(pulp & paper industry)

COPI - Companhia Operadora Portuária do Itaqui, Brazil

(Itaqi port operator, unloading, transporting and storing of fertilisers and other mass imports)RUMO MALHA NORTE SA, Brazil

(logistics for grain, fertilisers, soya and sugar)TERMINAL MARITIMO DO GUARUJA SA TERMAG, Brazil

(port terminal, unloading of fertilisers)VALE SA, Brazil

(mining)VLI MULTIMODAL SA, Brazil

(logistics for grain and mining)YARA BRASIL FERTILIZANTES SA, Brazil

(fertiliser production)Rio Tinto, Guinea

(mining)

Products for conveyor technology

Emergency pull-wire switches

Belt alignment switches

Belt-rip detection switches

Position switches