Requisitos especiales

Condiciones climáticas extremas, polvo fino o fuertes vibraciones de máquinas e instalaciones: los retos de la técnica de transporte como, por ejemplo, en la minería a cielo abierto, son enormes. En ocasiones, las cintas transportadoras empleadas deben transportar de forma fiable materias primas y materiales polvorientos o húmedos por recorridos de varios kilómetros. Si las cintas transportadoras se cargan de forma desigual dejan de desplazarse de forma centrada entre los rodillos transportadores, deberá corregirse el recorrido de la cinta o detenerse inmediatamente el sistema de cintas.

La tecnología de transporte es también un componente esencial de los procesos de fabricación y carga en muchos otros sectores, por lo que desempeña un papel decisivo en la eficacia de diversas aplicaciones. Debido al rápido crecimiento de la competencia internacional, especialmente en el campo de la tecnología de automatización, la mayoría de los procesos de producción están sometidos a una enorme presión para su optimización. Por eso es tan importante la fiabilidad de las cintas transportadoras y la capacidad de detenerlas de forma inmediata y segura en cualquier momento en caso de problemas de transporte o situaciones peligrosas.

Aparatos de conmutación para la protección en la tecnología de transporte

Dependiendo del ámbito de uso y la industria, los conmutadores deben poder utilizarse en diferentes cintas transportadoras en entornos muy duros y, al mismo tiempo, cumplir los requisitos de seguridad, resistencia a la corrosión y robustez. Por ejemplo, el interruptor de emergencia accionado por cable de steute implementa la función de parada de emergencia fiable y el control de rotura de cable en sistemas más grandes. El interruptor de desplazamiento espontáneo de cinta controla el correcto funcionamiento de las cintas transportadoras y asegura así el proceso de transporte de material pesado a granel.

Además de productos relacionados con la seguridad, steute ofrece una amplia gama de aparatos de conmutación y sensores que contribuyen especialmente a la automatización y optimización de los procesos de fabricación. Los sensores y los interruptores de posición inalámbricos permiten, por ejemplo, un uso flexible para el recuento automatizado y la supervisión de cargas unitarias en procesos de producción.

Los robustos aparatos de conmutación y sensores también están disponibles con alto grado de protección IP o en diseño a prueba de explosión.

Estructura de cinta transportadora

- Función de parada de emergencia

- Los interruptores de emergencia accionados por cable garantizan una función de parada de emergencia fiable, incluido un control de rotura de cable en sistemas de transporte

- Con modo de acción unilateral hasta 100 m o modo de acción bilateral hasta 200 m

- Control de posición de cinta transportadora

- Los contactos escalonados permiten a un mensaje de advertencia iniciar la corrección de la cinta

- Desconexión de la cintan si se acciona sucesivamente la palanca de desplazamiento espontáneo de cinta

- Los contactos de alerta temprana reducen el tiempo de inactividad de los sistemas de transporte

- Detección de rotura de cinta

- Desconexión automática del sistema en caso de sobrecarga de la cinta transportadora o de rotura de cinta

- Gran variedad de accesorios

- Resorte compensador ZS 90/91/92 S

- Cable de tracción Ø 5 mm

- Tornillo de armella M 10 x 150 con 2 tuercas

- Dispositivo tensor de cable TS 65

- Rodillo de desvío Multiflex 4R

Función de parada de emergencia gracias a interruptores de emergencia accionados por cable robustos

Los interruptores de emergencia accionados por cable de la serie ZS 92 S se desarrollaron desde cero para aplicaciones extremas. Están disponibles opcionalmente con una carcasa de aluminio fundido a presión muy robusta con múltiples revestimientos (pasivado, imprimación, recubrimiento pulvimetalúrgico) o, alternativamente, con una carcasa de duroplástico de alta calidad. Existen variantes 2G/D para las zonas Ex 1 y 21 así como variantes 3D para la zona Ex 22.

El interruptor de emergencia accionado por cable ZS 92 S implementa la función de parada de emergencia en sistemas de transporte, puede activarse en cualquier punto del cable y, por tanto, contribuye significativamente a la seguridad de las personas y las máquinas.

Opción de montaje posterior e inferior

La serie ZS 92 S se puede montar tanto en la parte trasera como en la inferior. Las dimensiones de conexión compatibles con otros interruptores de emergencia accionados por cable del mercado simplifican el reequipamiento o la sustitución en los sistemas de transporte existentes.

Disponible opcionalmente como variante Dupline Safe

El interruptor de emergencia accionado por cable ZS 92 S está disponible opcionalmente con regleta de enchufes Phoenix de 8 polos integrada y soporte para módulo de bus de seguridad. El módulo de bus de seguridad está disponible como accesorio en diferentes versiones y permite la conexión al protocolo orientado a la seguridad «Dupline Safe».

Extremadamente flexible gracias a varios «ajustes»

Los interruptores de emergencia accionados por cable ZS 92 S se pueden suministrar en diferentes «ajustes» para el ajuste de la palanca de desbloqueo y el desbloqueo. De este modo, pueden instalarse en casi cualquier posición imaginable.

Avisador luminoso LED

El interruptor de emergencia accionado por cable ZS 92 S está disponible opcionalmente con una lámpara de señalización LED. Cuando se activa el interruptor de emergencia accionado por cable, esta lámpara de señalización se ilumina en rojo para que se reconozca inmediatamente en qué punto del sistema se ha activado una parada de emergencia y es necesaria una intervención.

Numerosos accesorios innovadores para interruptores de emergencia accionados por cable

Los interruptores de emergencia accionados por cable son fundamentales para la seguridad en los sistemas de transporte industriales. Permiten activar una parada de emergencia en cualquier lugar a lo largo de las cintas transportadoras. No obstante, los accesorios adecuados son esenciales para optimizar el uso de estos interruptores y adaptarlos a las necesidades individuales. A continuación presentamos algunos accesorios de eficacia probada que amplían la funcionalidad y flexibilidad de los interruptores de emergencia accionados por cable.

Comparativa de instalación: Tensor y sujetacables vs. tensor de cable TS 65

Tensor de cable TS 65 - ¡rápido, sencillo, eficiente!

Menos pasos de trabajo, más eficacia Nuestro experto Matthias Schara se enfrentó al reto de instalación directa en la gravera Rhein-Umschlag: La instalación convencional de cable de tracción, aún muy extendida, con tensores, sujetacables y guardacabos compite con la instalación moderna con el innovador tensor de cable TS 65 de steute. El resultado: La instalación completa del cable de tracción solo lleva 42 segundos, en lugar de más de 9 minutos. El tensor de cable TS 65 no sólo ahorra una cantidad considerable de tiempo, sino que también reduce significativamente el número de pasos de trabajo y piezas individuales necesarias.

Equipo perfecto

Especialmente en sistemas en los que hay montados muchos aparatos de conmutación, el énfasis se pone en el factor tiempo y la facilidad de uso. Ceñirse a los métodos convencionales puede suponer un obstáculo al aumento de la eficiencia. Junto con el interruptor de emergencia accionado por cable ZS 92 S, el tensor de cable TS 65 forma un equipo inmejorable para facilitar considerablemente la instalación y ahorrar tiempo, dinero y mano de obra. Convénzase usted mismo en nuestro vídeo.

Más accesorios para interruptores de emergencia accionados por cable

Resorte compensador ZS 90/91/92 S

- Con limitación de carrera

- Para la compensación de variaciones de longitud en caso de fluctuaciones de temperatura

- Versión formada por: cadena de acero inoxidable, 2 mosquetones galvanizados y resorte de tracción

Tornillo de armella

- 150 mm de longitud, 70 mm de longitud de rosca

- Rosca M10

- Acero cincado

- 2 tuercas hexagonales incluidas en el suministro

Rodillo de desvío Multiflex 4R

- Desviación del cable de tracción hasta 90°

- Fricción reducida

- Montaje flexible

- Adaptación automática de la guía de cable mediante cabeza giratoria (360°) también para el cable de tracción

- Rodillos móviles dentro de la abertura de la polea de inversión

Cable de tracción Ø 5 mm

- Alma de acero o alma de acero inoxidable Ø 3 mm funda roja de PVC

- Diámetro total 5 mm

- Unidad de pedido: por metro

Aquí encontrará una vista de conjunto de nuestros versátiles accesorios para interruptores de emergencia accionados por cable.

Control de la posición de la cinta transportadora con interruptores de desplazamiento espontáneo de cinta de ajuste flexible

Los interruptores de desplazamiento espontáneo de cinta de la serie ZS 92 SR son auténticos especialistas para condiciones de funcionamiento extremas. Todos los productos de esta serie se caracterizan por una extraordinaria resistencia mecánica y están equipados con una carcasa de fundición de aluminio o una carcasa de duroplástico. También están disponibles las versiones Ex ZS 92 SR-2D (para polvo, zona 21) y Ex ZS 92 SR-3D (para polvo, zona 22), ambas con carcasa de aluminio fundido a presión.

Los interruptores de desplazamiento espontáneo de cinta controlan el funcionamiento de cintas transportadoras. La gran palanca de rodillos de acero inoxidable bascula hacia fuera si la cinta se descentra entre los rodillos, por ejemplo, porque está cargada de forma desigual. Dependiendo de la integración en el sistema de control, esto puede desencadenar una corrección del movimiento de la cinta o una parada de todo el sistema. La robusta construcción y el diseño especial para entornos extremos hacen de la serie ZS 92 SR una solución fiable para aplicaciones exigentes.

Los contactos escalonados permiten a un mensaje de advertencia iniciar la corrección de la cinta

Los contactos escalonados con puntos de conmutación ajustables individualmente pueden calificarse como sobresalientes. Los puntos de conmutación de la preadvertencia y la desconexión pueden ajustarse en un rango de 5° - 35°. Esto es posible gracias al simple desbloqueo, desplazamiento y bloqueo de los elementos de conmutación. El interruptor puede emitir primero un mensaje de advertencia, y si se desvía en mayor medida, hace que la cinta se desconecte. Estos «contactos de alerta temprana» reducen el tiempo de inactividad del sistema de transporte: El operario tiene la posibilidad de intervenir antes de que se detenga la cinta.

Varias versiones para ajustar la palanca de rodillos

Existen versiones con eje estriado (unión en arrastre de forma), que permiten cambiar el eje rápidamente, así como versiones con eje ajustable de forma continua, que permiten adaptar la posición básica de la palanca de rodillos a la aplicación individual.

Avisador luminoso LED

El interruptor de desplazamiento espontáneo de cinta ZS 92 SR está disponible opcionalmente con una lámpara de señalización LED que muestra el estado de conmutación. Esto permite ver a distancia si la cinta se mueve descentrada en el sistema transportador.

Innovadora solución inalámbrica para controlar el desplazamiento espontáneo de cintas

La combinación del probado interruptor de desplazamiento espontáneo de cinta ZS 92 SR con un módulo de radiofrecuencia RF I/O independiente abre nuevas posibilidades para un control eficaz y sin problemas de los sistemas de transporte. La unidad transmisora utiliza la tecnología sWave para transmitir las señales del interruptor a un módulo de relé de radiofrecuencia, que actúa como unidad receptora. La transmisión se realiza de forma fiable y sin conexión por cable a distancias de hasta 400 metros en campo abierto. Se pueden instalar repetidores adicionales para distancias mayores.

Este robusto sistema de conmutación de radiofrecuencia ofrece ventajas significativas, sobre todo en entornos difíciles, y combina las competencias básicas de steute en los ámbitos de los aparatos de conmutación y la tecnología inalámbrica.

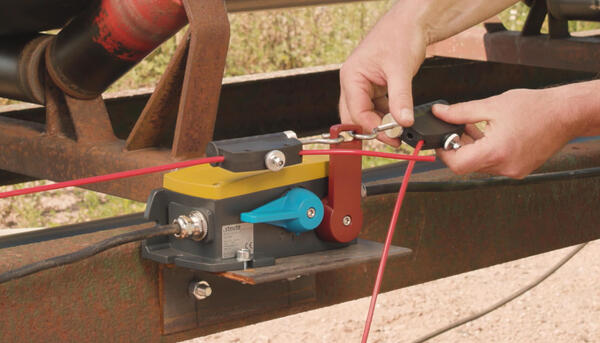

Detección de rotura de cinta gracias a un innovador sistema de control de rotura de cinta

No deje que una simple grieta en su cinta transportadora provoque un fallo catastrófico y costosos tiempos de inactividad. El interruptor de control de rotura de correas ZS 71 y el sistema de cables pueden proteger sus operaciones mediante la detección precoz y una intervención rápida. Con sus funciones de última generación, su robusta construcción y su diseño de fácil manejo, el interruptor de control de rotura de cinta ZS 71 ofrece seguridad y productividad continua. El ZS 71, en combinación con el extenso sistema de cables, permite una solución completa para el control de rotura de cinta. Si un objeto extraño o material a granel daña y penetra en la cinta en los puntos de transferencia, quedará atrapado en el cable. Esto hace que el interruptor se accione y que el transporte se detenga.

Gracias a su rápida detección y respuesta inmediata a las roturas de cinta, el interruptor minimiza considerablemente los tiempos de inactividad del sistema transportador y le ahorra tiempo y recursos valiosos. El interruptor de control de rotura de cinta ZS 71 es compacto y está diseñado para que pueda instalarse en ángulo recto con la cinta transportadora, incluso en situaciones de instalación en espacios reducidos.

Estructura del sistema de control de rotura de cinta

- Interruptor de control de rotura de cinta ZS 71

- 1 x mosquetón (acero inoxidable)

- 1 x llavero (acero inoxidable)

- 1 x acoplamiento de seguridad

- 2 x abrazaderas de plástico

- 5 m cable metálico, Ø 3-5 mm PVC rojo

- 1 x tensor de cable TS 65

- 2 x armellas BM 8x70 (acero inoxidable) con 2 tuercas

- 2 x guía de cable (acero inoxidable) con 2 x tuercas M10 y arandelas

La cinta transportadora puede protegerse con uno o dos sistemas de control de rotura de la cinta.

Sistema de cables completo

El acoplamiento de seguridad integrado desconecta de forma segura el interruptor de control de rotura de cinta del sistema de cable en caso de sobrecarga mecánica (> 250 N). A continuación, puede volver a conectarse fácilmente.

Referencias

Nuestras soluciones se utilizan en una gran variedad de proyectos y ámbitos en todo el mundo y abarcan una amplia gama de industrias. Aquí encontrará una selección de empresas de renombre que utilizan con éxito productos steute:

- Herrenknecht / H+E Logistik GmbH, Germany

(tuneladoras y construcción de túneles) - STM Industriale S.P.A., Italy

(sistemas de transporte) - Rhein-Umschlag GmbH, Germany

(graveras y areneras) - Mineraria Ligure S.r.l., Italy

(producción de polvos, guijarros y granulados de mármol) - VHV Anlagenbau, Germany

(tecnología de transporte) - alco energy, Netherlands

(biorrefinerías) - ABB, Germany

(autómatas) - AMAGGI Exportacao e Importacao Ltda, Brazil

(transformación de cereales y abonos) - CENIBRA Celulose Nipo-Brasileira S.A., Brazil

(producción de pasta de celulosa e industria papelera)

- COPI - Companhia Operadora Portuária do Itaqui, Brazil

(empresa operadora del puerto de Itaqui, servicios de descarga, transporte y almacenamiento de fertilizantes y otros productos a granel importados) - RUMO MALHA NORTE SA, Brazil

(empresa de logística de cereales, fertilizantes, soja y azúcar) - TERMINAL MARITIMO DO GUARUJA SA TERMAG, Brazil

(terminal portuaria, descarga de fertilizantes) - VALE SA, Brazil

(minería) - VLI MULTIMODAL SA, Brazil

(empresa logística para cereales y minería) - YARA BRASIL FERTILIZANTES SA, Brazil

(producción de fertilizantes) - Rio Tinto, Guinea

(minería)

Productos para la técnica de transporte

Interruptores de emergencia accionados por cable

Interruptores de desplazamiento espontáneo de cinta

Interruptores de control de rotura de cinta

Interruptores de posición