Hydrogen technology is advancing, the infrastructure is emerging. Accordingly, the demand for valves which regulate hydrogen flow in networks, but also in power generating and distribution systems, as well as for consumers, will increase.

The positions of these valves will in turn require monitoring. When selecting switches or sensors for valves, it is vital to remember that hydrogen is explosive. In Europe, the gas explosion protection regulations according to the ATEX directive also apply. And when selecting the valves themselves, it should be noted that the sealing requirements are very high because the pressure level can reach 700 bar and the hydrogen molecules are extremely small.

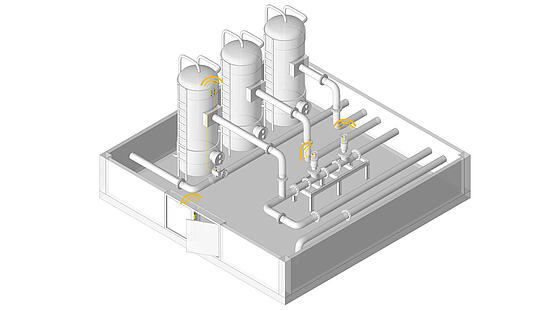

These factors all point to the Ex RF 96 series of Wireless Ex position switches from the steute Controltec range. A switch detects the position of the valve and transmits a wireless signal to the receiver unit (usually installed outside the Ex zone) via the sWaveâ wireless technology developed by steute.

In many application fields within the hydrogen infrastructure, a sensor (as opposed to an electromechanical switch) can be the better monitoring solution. Valves used in explosive zones often have an insulated or encapsulated pressure chamber. The valves are controlled by solenoids, and position monitoring is also contact-free.

To serve applications like this, the steute division Controltec has developed the Ex IS series of Ex-protected inductive sensors for Ex zones 1 and 2 with long sensing distances. They allow the current valve position to be monitored and do not require a "target" as a counterpart because they detect the position of the valve spindle directly – simplifying installation.

With the wireless version of its gas Ex inductive sensors, steute is moving another step closer to "industry-compatible valve position monitoring in the hydrogen infrastructure". In combination with the Ex RF 96 ST radio module, the Ex RF IS can communicate with the corresponding receiver unit (installed outside the Ex zone) via the robust sWaveâ wireless protocol. Signals are exchanged between the sensor and the receiver unit using the sWaveâ wireless technology, which can be adapted to different national frequency requirements (868, 915, 917 and 922 MHz).

The sensor is powered by a lithium battery which can be replaced inside the Ex zone. This type of energy supply permits the use of additional functions, such as switch monitoring via status signal, and optimisation of wireless transmission via LBT (listen before talk) technology.

Moreover, battery power simplifies installation under Ex conditions, and it also means that Ex-compatible cabling can be eliminated – a solution which is both efficient and elegant, and which has already been implemented by multiple valve manufacturers.

„Wireless Ex“sensors for valve monitoring in hydrogen infrastructure

Files:

position_switches_explosive_environments.tif

tif | 13 MB

valve_monitoring.jpg

jpg | 666 KB

position_switch.jpg

jpg | 1 MB